Johanes Wongsodinata of PT. Pentra Unggul Sejati Indonesia

Oil and Gas Company, Indonesia

November 2019

PROBLEM

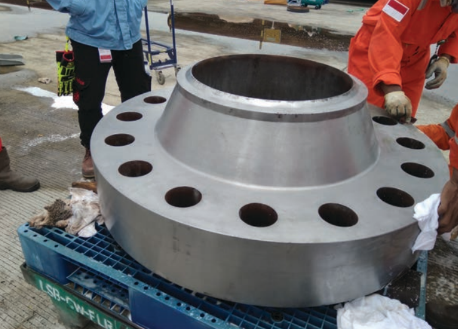

The customer had problems with corrosion on critical oil and gas equipment (flanges, valves, etc.) and asked Pentra if Cortec® had a solution.

APPLICATION

Pentra visited the site in August 2018 to review the prob-lem and conduct a field trial. During the visit, Pentra found that some of the critical equipment had already been used and would need to be restored before preser-vation. Fortunately, Cortec® also had a solution for this, and Pentra was able to offer to perform the work in a two-stage process.

The first step was surface preparation. This included the use of MCI® Super Remover to clean off any mud or hardened soil present on used equipment. VpCI®-423 was applied as needed to remove rust, and VpCI®-416

was used to rinse the equipment.

The second step was protection before storage. Pen-tra used a variety of Cortec® integrated corrosion so-lutions depending on the needs of each component.

CorShield® VpCI®-369, VpCI®-389, and VpCI®-391 re-movable coatings were applied as needed to different metal surfaces. VpCI®-337 was used to fog internal

void spaces. Equipment was wrapped in either VpCI®-126 Shrink Film or MilCorr® VpCI® Shrink Film, de-pending on the expected length of storage or the sever-

ity of the storage conditions.

Need Any Help?

Technical : +62 821 2258 3828

technical@pentra.co.id